Chiranjeev Group

It's All About Engineering

It's All About Engineering

Welcome

We continually look forward to applying our skills in new technologies and applications that improve the way to serve our customers.

This commitment to customer service has produced an unrivaled source of best-in-class solutions drawn from abroad range of products, services.

Our commitment to these principles makes us a more cohesive, focused and progressive company that benefits each member of the Chiranjeev Group Group.

This commitment to customer service has produced an unrivaled source of best-in-class solutions drawn from abroad range of products, services.

Our commitment to these principles makes us a more cohesive, focused and progressive company that benefits each member of the Chiranjeev Group Group.

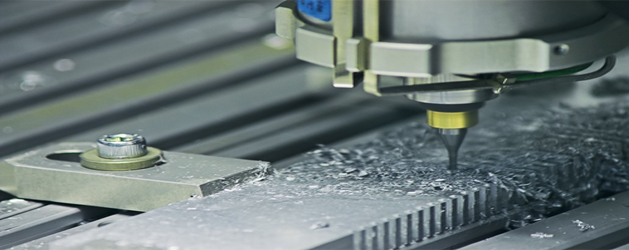

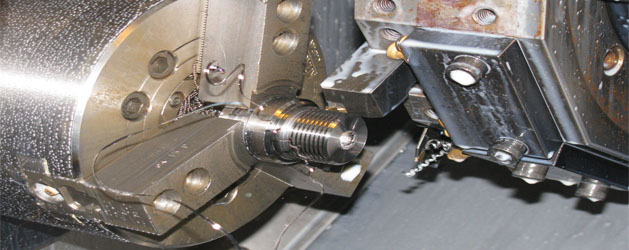

Our Manufacturing Capabilies

Manufacturing

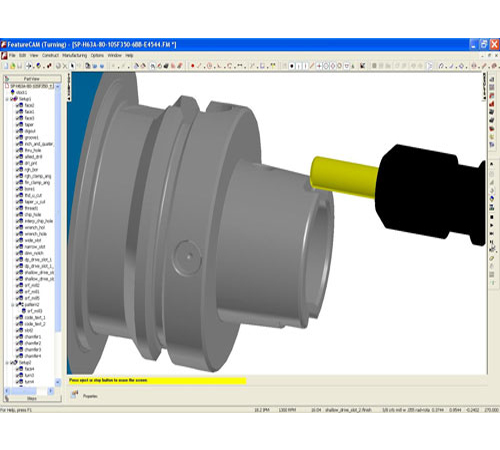

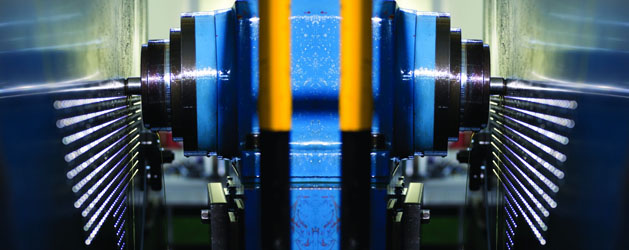

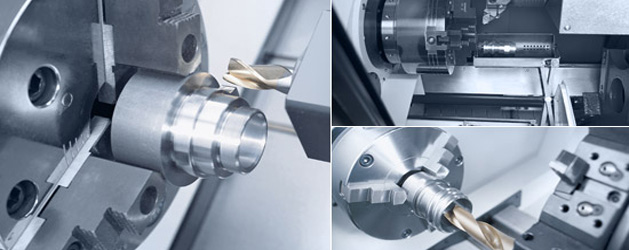

CNC TURNING :

|

|||||||||||||||||||||||||||||||||

Quality and Inspection

Chiranjeev Group has reactive precision machining market that the company is positioned in, necessitates the use of a wide range of machinery with accuracy, repeatability, and reliability.

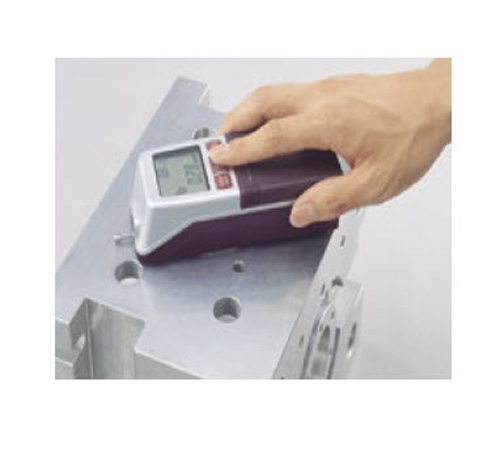

Company uses Accurate CNC Co-ordinate Measuring Machines (CMM). 1. CNC CO-ORDINATE MEASURING MACHINE (CMM) Make : Accurate (India) Model : Spectra Series Size : 500*800*400 2. SURFACE ROUGHNESS TESTER Make : Mitutoyu Model : SJ 201 3. HARDNESS TESTING MACHINE 4. LEAKAGE TESTING MACHINE 5. MICROSCOPE |

|

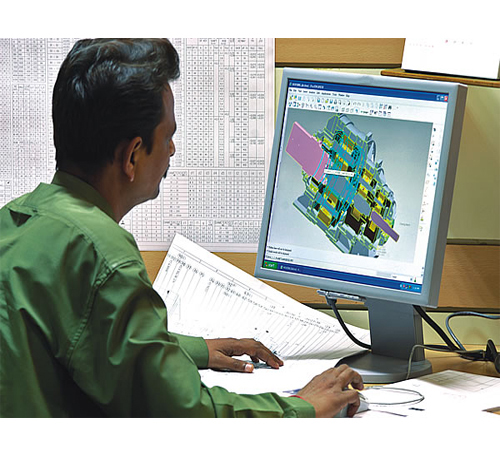

CAD Design and Prototyping

- Chiranjeev Group provides economical CAD designing services & CAM manufacturing with high quality results to our customers.

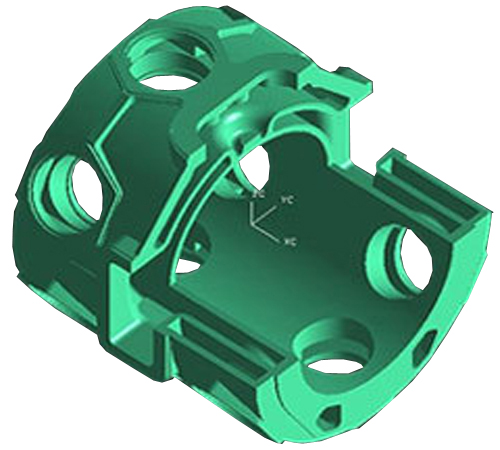

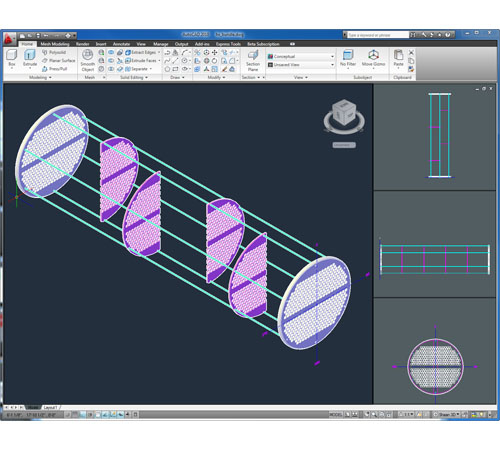

1. 3D Design

Using the latest software to produce 3D CAD models and meet the clients requirements. The 3D CAD models may be used for an array of different applications whether it is for photorealistic CAD visuals, rapid prototype models or even components.

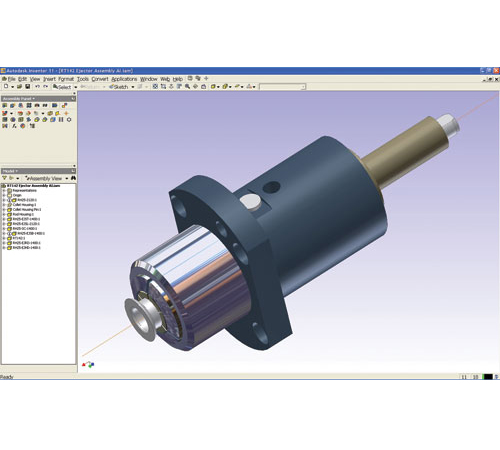

2. Production

Once the 3D model is produced we can produce all manufacturing detailing, including mould draft, split lines, gate and ejector positions. 3D IGES files can then be created to be used directly with the manufacture of the mould tool or component his ensuring the components are precise.

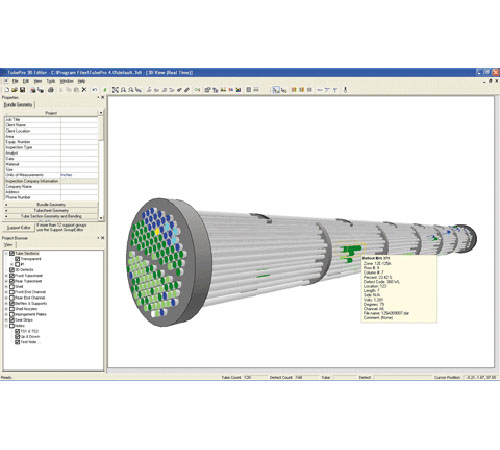

3. Reverse Engineering

Whether it is the traditional methods of measurement or using non-contact technology we have the ability to generate, using tools available within a number of CAD packages, models that match the data exactly. This can then be delivered in any neutral file format.

4. Prototypes / 3D Printing

Whether it is the traditional methods of measurement or using non-contact technology we have the ability to generate, using tools available within a number of CAD packages, mod

- Our engineers conduct following tests on solid models 1 Fatigue & crack test 2 Thermal analysis 3 Structural analysis 4 Mechanical stress analysis 5 Functional Test 6 Life cycle test - With the above , We can guarantee you long lasting high performance of our product. |

|